Fabrication

Expansion Joints

1. Fabric Expansion Joint

Fabric Expansion Joint are widely used in the Power Plant Industry. However, Continuous development in Design Concept, combined with the dynamic creativity of Design Frame has put - a highly promising option to be widely used in many other applications. Our Fabric Expansion Joints have been applied in the loop of many other:

Major industries such as:

- Pulp and Paper

- Plants

- Power Plants

- Refineries (Oil & gas)

- Steel Mills

- Foundries

- Cement Plants

- Food Processing, and many others

2. Metal Expansion Joints

3. Rubber Expension Joint

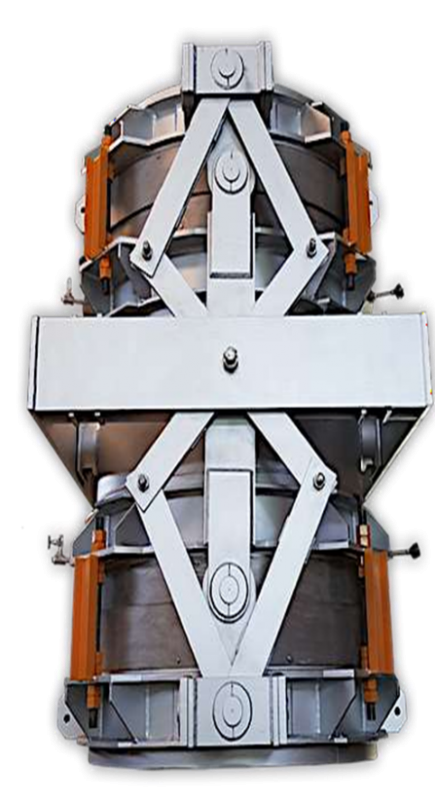

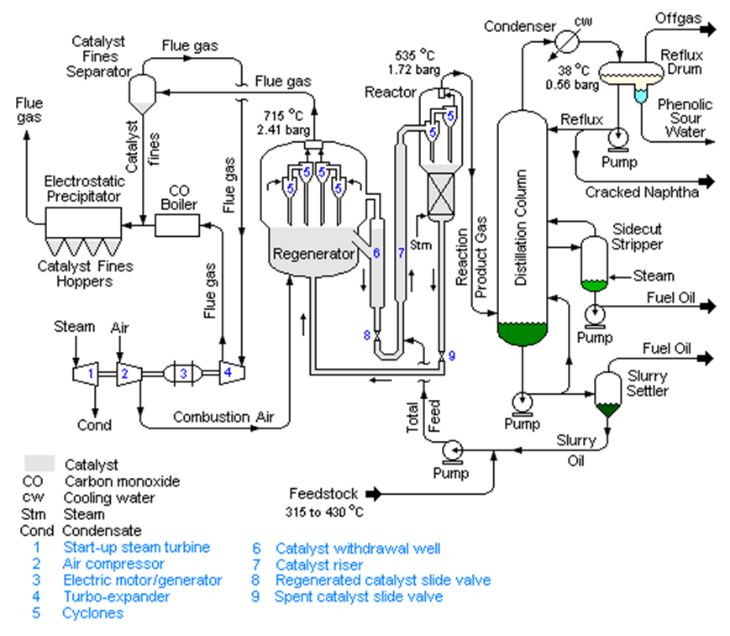

FCCU - FLUID CATALYST CRACKING UNIT

FCCU being the most critical part of any refinery which operates on very high pressure and extremely high temperature +1000 degree C , consequently resulting in large movement while operating in the most abrasive and corrosive media.

Strainer

Cone Type Strainer

Applicable Code: ASME, KS, JIS, JPI, API, ISO, MSS

Material: Carbon Steel, Stainless Steel, Alloy Steel, Monel, Aluminium, Copper Alloy, Chrome Steel, etc.

Flange Rating: 150#, 300#, 600#, 900#, 1500#, 2500#

Size Range : 1/2” and above

Y-Type Strainer

Applicable Code : ASME, KS, JIS, JPI, API, ISO, MSS

Material : Carbon Steel, Stainless Steel, Alloy Steel, Monel, Aluminium, Copper Alloy, Chrome Steel, etc.

End Connection : Socket Weld Type, Flange Type, Screw Type (PT & NPT), Butt Weld Type

Flange Rating : 600#(API 800#), 1500#, 2500#

Size Range : 1/2” ~ 2”

T-Type Strainer

Applicable Code : ASME, KS, JIS, JPI, API, ISO, MSS

Material : Carbon Steel, Stainless Steel, Alloy Steel, Monel, Aluminium, Copper Alloy, Chrome Steel, etc.

End Connection : Flange Type, Butt Weld Type

Flange Rating : 150#, 300#, 600#, 900#, 1500#, 2500#

Size Range : 2” and above

Basket Type Strainer

Applicable Code : ASME, KS, JIS, JPI, API, ISO, MSS

Material : Carbon Steel, Stainless Steel, Alloy Steel, Monel, Aluminium, Copper Alloy, Chrome Steel, etc.

End Connection : Flange Type, Butt Weld Type

Flange Rating : 150#, 300#, 600#, 900#, 1500#, 2500#

Size Range : 1/2″ ∼ 24”

Duplex Type Strainer

Applicable Code : ASME, KS, JIS, JPI, API, ISO, MSS

Material : Carbon Steel, Stainless Steel, Alloy Steel, Monel, Aluminium, Copper Alloy, Chrome Steel, etc.

End Connection : Flange Type, Butt Weld Type

Flange Rating : 150#, 300#, 600#, 900#, 1500#, 2500#

Size Range : 1/2″ ∼ 24”

Filter

Filter Housing - Cartridge Filter Housing

MS Type

- Standard Model

- It is possible to design for special case also such as high-pressure, high temperature according to condition of field use

MC Type

- It is used a lot as automatic reverse-wash equipment, because it is easy to release pollution material

- It can gain better filtration efficiency when filtering gas

MCL Type

- Coating & Lining Housing Rubber / Teflon / Polypropylene / FRP

Filter separator (MFS Type)

(MFS-Type)

MSNT two stage filter separator technology allows you to have the smallest possible vessel diameter, resulting in the lowest cost while removing aerosol liquids and solid particles efficiently.

The first stage contains replaceable coalescing filters mounted on a tube sheet. Here the bulk liquids and solids are removed while coalescing the aerosol liquid droplets into large ones. Some of these coalesced droplets fall off the filter but the majority is pushed to the second stage due to the high surface velocity.

In the second stage, these large droplets are removed by a high capacity Double Pocket Vane and Mesh Pad.

Features:

- Removes aerosol mist to protect downstream equipment from damage, fouling, pitting corrosion or deactivating of catalyst of molecular sieves

- Reduces amine or glycol foaming problems by removing solids and free liquid particles from the inlet gas stream

- Allows low cost vessel designs

- Debottleneck existing equipment, and adding upto 100% more capacity without requiring a new separator

Filter Separator (MRGC Type)

Reverse Flow Gas Coalescer

(MRGC-Type)

Remove liquid and solid particles entrained in gas Efficiency of 99.5% removal of particles 0.3㎛ 100% turndown

Applications:

- Removal of Lube Oil Downstream of Compressor

- Inlet to Gas Turbines

- Inlet to Molecular Sieve Plant

- Low NOx Applications

There are 3 mechanisms that enable droplets to coalesce on the surface of the element:

- Sieving

- Impacting

- Diffusion

Sizing Considerations

- Inlet nozzle velocity and pressure drop

- Bulk liquid removal / stilling screen

- Velocity through risers

- Liquid loading per element

- Liquid loading per element

- Element spacing / gas velocity

- Vapour disengagement

- Outlet baffle sizing

- Outlet nozzle velocity and pressure drop

Coalescer (MLL Type)

Liquid-Liquid Coalescer

(MLL-Type)

MSNT high-efficiency coalescer is recommended for a wide range of gas & liquid filtration process. A coalescer is a technological device performing coalescence.

It’s primarily used to separate emulsions into their components via various processes, operating in reverse to an emulsifier.

MSNT can supply Coalescer according to fluid material which needs to be separated. (Liquid-Liquid / Liquid-Gas / Three Phase Separation)

Features:

- Reduces cost due to smaller vessel design

- Capacity increase for the existing vessels

- Higher recovery of valuable products

- Removal of haziness in the product

- Reduces blending delays

- Reduces wastewater production from tankage, separator, and desalter