Sealing

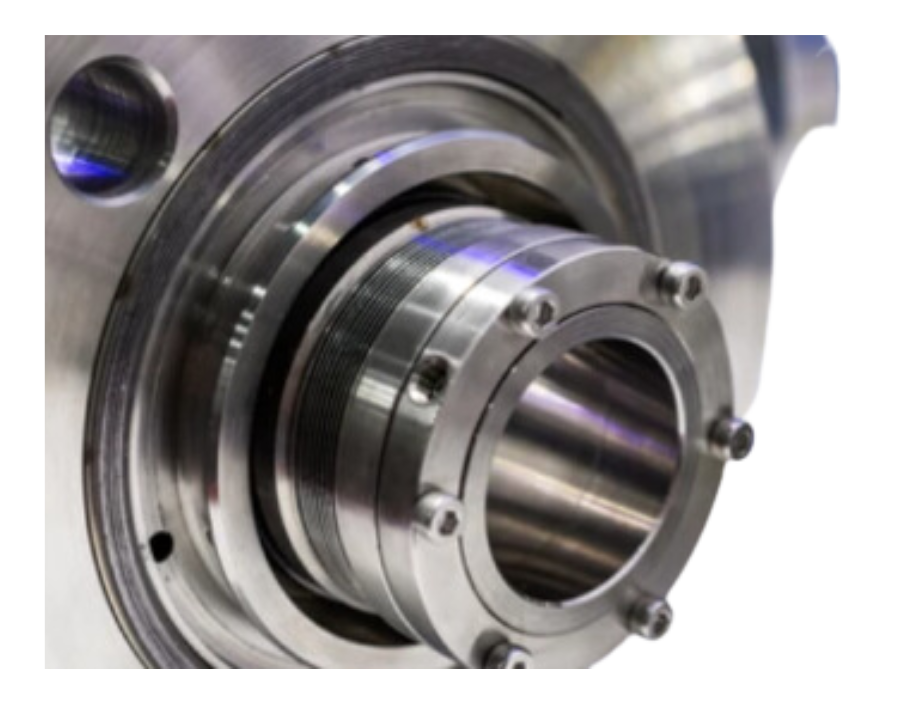

MECHANICAL SEALS

To stop liquids and gases from leaking into the environment, a variety of pumps and spinning equipment employ our mechanical seals. We offer mechanical seals for every industry, and because we invested in modular design, we have the highest industry-wide on-time delivery performance.Proper selection, installation, and maintenance of mechanical seals are essential for their effective operation and to avoid issues like leakage, wear, and premature failure.

✅ Leak Prevention

✅ Enhanced Safety

✅ Extended Equipment Life

✅ Improved Efficiency

✅ Ease of Maintenance

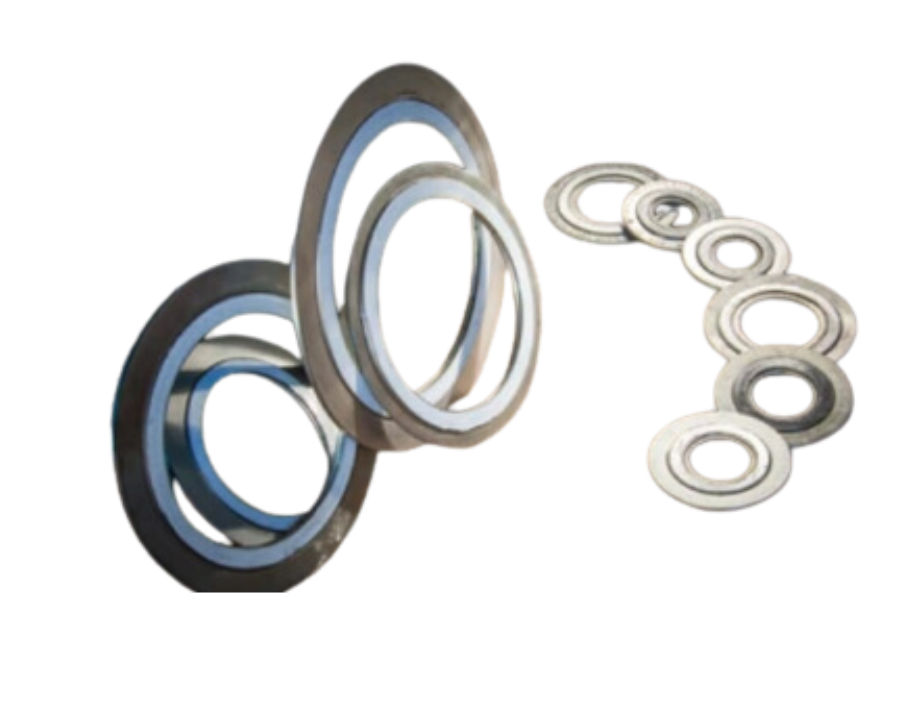

METALIC GASKET

Materials include Inconel 600, Inconel 625, Inconel 800, Inconel 825, SS304L, SS316, SS316L, SS304H, SS316H, SS321, SS410, Duplex 31803, Duplex 32205, Duplex 32750, Duplex 32760, and Monel.

Gasket Type We Provide :

- Metallic – Ring Joint Gasket (Style R, Style, RX, Style BX)

Features:

- Enhanced Stability: Some designs include outer and inner rings to improve gasket stability and prevent blowouts.

- Precision Engineering: Manufactured to exact specifications to ensure a perfect fit and optimal sealing performance.

- Wide Range of Applications: Suitable for use in flanges, heat exchangers, valve bonnets, and other critical sealing points

Benefits:

- High Temperature and Pressure Resistance: Designed to withstand extreme conditions,provide reliable sealing even in high-temperature and pressure environments.

- Durability: Constructed from robust metal materials, these gaskets offer long-lasting performance, reducing the need for frequent replacements.

- Chemical Resistance: Metallic gaskets are resistant to a wide range of chemicals, making them suitable for use in aggressive and corrosive environments.

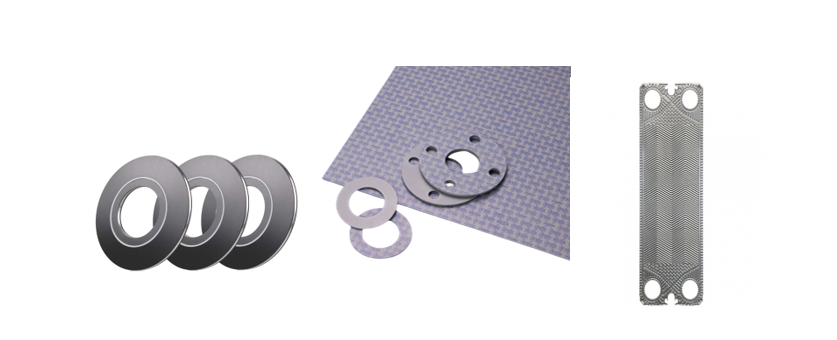

NON-METALIC GASKET

Non-metallic gaskets can be custom-cut to fit specific shapes and sizes, which adds to their versatility in sealing applicationsWe offer a wide selection of elastomers, compressed non-asbestos, PTFE, flexible graphite, and high temperature sheet goods to meet all of your application demands.

Gasket type we provide:

- Soft Cut – PTFE Gasket, Graphite Gasket, Rubber Gasket, Insulation Kit Gasket, Compressed Fiber Sheet Gasket (Non-Asbestos)

Features:

- Variety of Shapes and Sizes: Available in numerous shapes and sizes to fit standard and custom flanges and connections.

- Compressibility and Recovery: Non-metallic gaskets are designed to compress under pressure and recover their shape, ensuring a tight seal.

- Resistance to Wear and Tear: These gaskets are durable and resistant to wear, prolonging their lifespan and maintaining performance.

- Customizable: Can be tailored to meet specific application needs, including custom dimensions and material compositions.

Benefit:

- Cost-Effective: Generally less expensive than metallic gaskets, they provide a cost-effective sealing solution without compromising quality.

- Ease of Installation: Lightweight and flexible, non-metallic gaskets are easy to handle and install, reducing labor costs and time.

- Wide Application Range: Ideal for use in piping systems, flange joints, and equipment across numerous industries including water treatment, food processing, and pharmaceuticals.

- Temperature Flexibility: Non-metallic gaskets can perform effectively across a broad temperature range, ensuring reliability in various conditions.

SEMI METALIC GASKET

Semi-metallic gasket that is suitable for critical equipment and for commonly used as sealing on pipe joints, we have a wide range of size and rating readily available .

Gasket Type We Provide :

- Spiral Wound Gasket, Kamprofile Gasket, Jacketed Gasket

SPECIAL GASKET

For hostile chemicals, cryogenic, fire-safe, fugitive emissions, high temperature, and high pressure, we provide specialised gasket solutions. Engineers and manufacturers work closely to select or design the most appropriate gasket material and type to ensure the desired performance characteristics are met, whether it’s for extreme temperatures, electromagnetic compatibility

We are glad to offer the following Special Gasket as part of our strategy to provide consumers with a larger selection of products:

Pikotek , Valqua, PHE

SPIRAL WOUND GASKET

Spiral wound gaskets are the ultimate solution for your sealing needs, designed to excel in the most demanding environments. Whether you operate in the oil and gas industry, petrochemical plants, or power generation facilities, our spiral wound gaskets offer unmatched performance and reliability.

We offer spiral wound gaskets in sizes ranging from 1/2 inch to 36 inches and pressure ratings from 150# to 1500#, accommodating a wide variety of industrial needs.

Features

- High-Quality Materials: Crafted from premium stainless steel and high-performance filler materials.

- Outer and Inner Rings: For improved stability, centering, and protection against blowouts.

- Customizable Sizes: Available in various sizes and configurations to meet your specific needs.

Benefit

- Superior Sealing: Combines metal strength and filler flexibility for excellent sealing.

- Durable: Withstands high pressure and temperature, reducing replacements.

- Versatile: Suitable for various applications like flange joints, heat exchangers, and valve bonnets.

- Cost-Effective: Reduces maintenance costs and downtime.

- High-Quality Materials: Made from premium stainless steel and high-performance fillers.

- Enhanced Stability: Outer and inner rings provide stability and prevent blowouts

GLAND PACKING

For the needs of users and original equipment manufacturers of pumps and valves, we provide a wide variety of non-asbestos packing options.

Based on the designation of decreasing leakage and sealing purposes for various applications, the type of gland packing is chosen. Environmentally friendly (replacement of asbestos). International Standard Composition

Specification:-

Application: Chemical Resistant, Refiners, Pump, Valve, Piston

Medium: Water, Air, Steam, Mild Acid, Alkalis etc.

pH: 2 ~ 14

Max Temperature: 150°C ~ 600°C

Max Pressure: 20kgf/cm2 ~ 260kgf/cm2