Expansion Joint

FABRIC EXPANSION JOINT

High-end engineering considerations and materials are used in the design and production of our fabric expansion joints. We provide several forms of fibreglass coating, laminated PTFE-coated fibreglass for single layer, or to be further combined as a Multi Layer Fabric Expansion Joint, making it ideal for all significant industries. Elastomers such as EPDM, Neoprene, or FKM are also available.

Standard

Fabric Expansion Joints are designed in accordance with ASME Section VIII, Division 1 | ASTM, ANSI, and EJMA | ASW | FSA.

Product Range

High quality Expansion Joint for low temperature

Material: Single or Multilayer Construction

Temperature: 50 ~ 300 Deg. C (max)

Pressure: 0.3 barG

Multiple layer & Versatile Expansion Joint

Material: Multilayer Construction

Temperature: 400 Deg. C (max)

Pressure: 0.3 barG

Adaptable, Resistance & Versatile Expansion Joint

Material: Multilayer Construction

Temperature: 600 Deg. C (max)

Pressure: 0.3 barG

Extreme condition, custom made Expansion Joint

Material: Multilayer Construction

Temperature: 1300 Deg.C and above.

Pressure: 0.3 barG

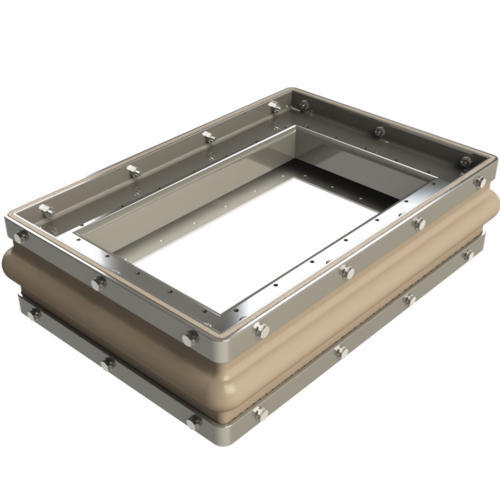

METAL EXPANSION JOINT

Expansion joints are essential for maintaining safety and compliance with industry standards and regulations, particularly in applications where temperature and pressure fluctuations are significant. Manufacturing sizes range from 50mm to 6000mm, with shapes including rectangular, circular, thick wall, and cold spun, as well as different configurations (e.g., tied, hinged).

STANDARD:

Metal Expansion Joints are designed in accordance with EJMA 10th Std or ASME Sec.VIII Div.I App. 26 or ASME B 31.3 or EN13445.

MATERIAL:

Stainless steel

Incoloy

Inconel

Hastelloy

Titanium

Monel

Use: to transport several types of media, such as steam, emission gases, water, acid, alkali, and hydrocarbon.

TYPES :

Single Expansion Joint

Universal Tied Expansion Joint

Pressure Balanced Expansion Joint

Double Hinged Expansion Joint

Gimbal Expansion Joint

Double Hinged Expansion Joint

Single Tied Expansion Joint

RUBBER EXPANSION JOINT

Our rubber expansion joints surpass the stringent specifications demanded by the pipe and ducting industry. Leveraging unique engineering principles and advanced design tools, our products adhere to a wide range of international standards, ensuring superior performance and reliability. They provide exceptional flexibility and durability, meeting and exceeding industry expectations.using unique engineering principles and design tools that are in accordance with a wide range of international standards, including ASME Code Section VIII, the Standards of Fluid Sealing Association (FSA), the Standards of Expansion Joint Manufacturers Association (EJMA), the Pressure Equipment Directive (PED), and other ASTM Standard Specification.

Standard:

ASTM F1123: Standard Specification for Non-Metallic Expansion Joints.

DIN 4809: Rubber Expansion Joints – Requirements and Testing.

FSA/NFPA: Fluid Sealing Association / National Fire Protection Association guidelines.

EJMA: Expansion Joint Manufacturers Association standards for design and manufacturing.

Components:

Rubber Body: The main flexible part made of natural or synthetic rubber.

Reinforcement: Fabric or metal reinforcements embedded in the rubber body for added strength and durability.

End Fittings: Flanges, unions, or threaded ends for connecting to piping systems.

Inner Liner: Optional layer inside the rubber body for added chemical resistance.

Outer Cover: Protective layer to shield against environmental damage.

We offer a wide variety of design to meet various piping system requirements such as:

• Pressure

• Temperature

• Movement

• Stiffness

• Fluid resistance